In an increasing number of bathroom upgrade solutions, a hardwired led bathroom mirror with switch is becoming a frequently adopted lighting and functional integration option. Unlike plug-in mirrors, hard-wired LED mirrors are often seen as a more "permanent" and cleaner solution. But the question that comes with it is: how should this mirror be installed? Do you really need a professional electrician? Is the installation process more complicated than imagined?

1. Why are more and more LED mirrors choosing hard-wired methods?

From a product design perspective, hardwiring is not intended to increase installation difficulty but to reduce visual interference. There is no exposed power cord, and the overall feel between the mirror and the wall is more substantial, particularly evident on bathroom mirrors 30-48 inches wide.

In addition, hard-wired mirrors with wall switches can be directly integrated into existing lighting systems. Data shows that in bathroom lighting renovations, more than half of users prefer to control the lights uniformly through wall switches rather than repeatedly touching mirrors, which is also an essential reason for the continued growth of hard-wired solutions.

2. Preparation before installation is more important than the construction itself

What truly determines the smoothness of installation is not the wiring action, but the early judgment of whether it is in place.

Firstly, the power supply location.

Ideally, the embedded power box should be located at the center or above the mirror, at a height of 60-70 inches from the ground, making it easy to hide the circuit without affecting the fixed structure.

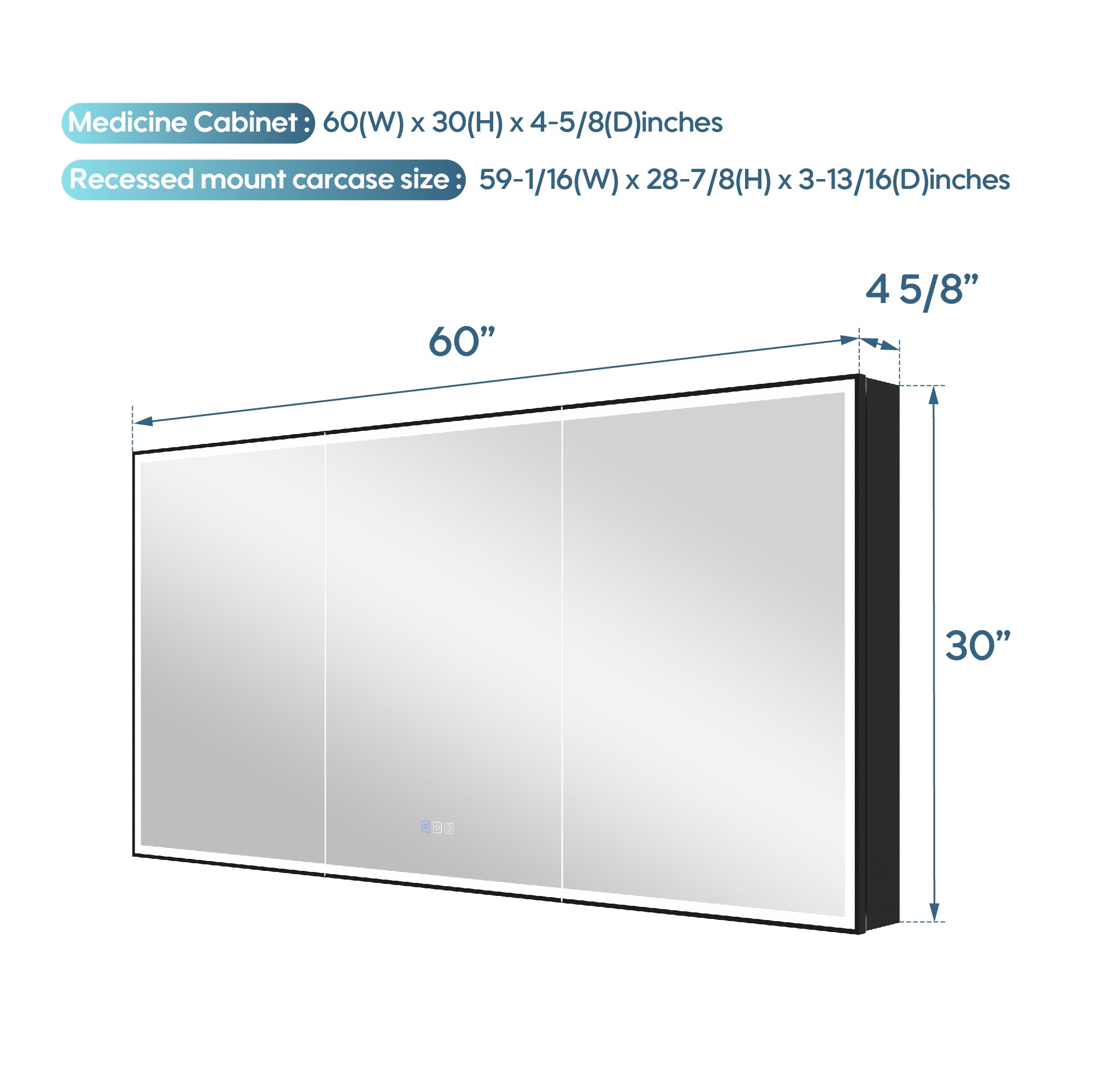

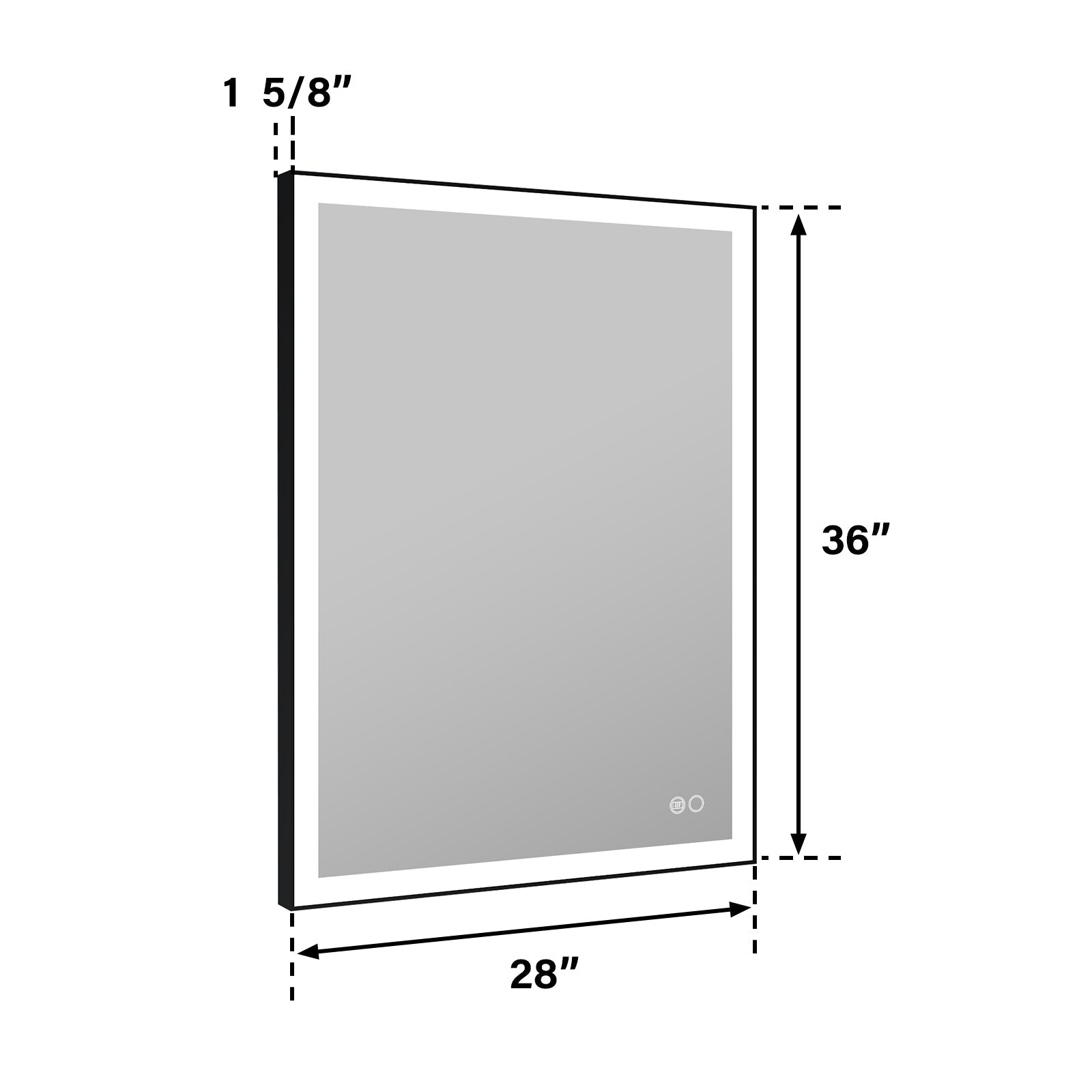

Next is the size and weight of the mirror.

The weight of ordinary LED bathroom mirrors ranges from 20 to 45 pounds, and the wider the mirror, the heavier it is. Mirrors over 36 inches are usually recommended to have at least one side fixed to the wall keel to ensure long-term stability.

Finally, confirm the switch type.

Mirrors with independent wall switches usually require confirmation of whether they are single- or dual-control circuits and whether they share the same wiring with existing lighting fixtures, which will directly affect the wiring method.

3. For a hardwired installation, the core steps are not complicated

From a process perspective, installing hard-wired LED mirrors can be broken down into several straightforward steps.

The first step is to disconnect the power and confirm the circuit is disconnected.

Cutting off the corresponding circuit power supply is a fundamental prerequisite before any operation. Confirming the position and status of the live, neutral, and grounding wires is the foundation for subsequent safety.

The second step is to fix the pendant or backboard.

Most LED mirrors use a back-mounted design, with metal hanging strips or mounting plates first attached to the wall. For mirrors with a width exceeding 40 inches, it is usually necessary to have two or more fixed points and ensure that the horizontal error is controlled within an acceptable range.

The third step is the electrical connection.

Connect the power cord inside the mirror to the wiring inside the wall through terminal blocks. A mirror with a wall switch controls the live wires' on/off through the switch, enabling unified lighting switching. The entire process does not involve complex electronic components, but relatively standardized wiring operations.

The fourth step is installation and testing.

After the wiring is completed, hang the mirror body in the fixed structure, restore power, and test whether the switch response, brightness, and function are normal.

Under ideal conditions, the construction time for this entire process is usually between 1.5 and 3 hours.

4. How much difficulty will it increase with a switch design?

From a practical construction perspective, 'with switch' does not significantly increase the difficulty. Most of these mirrors do not have built-in independent physical switches, but are designed to be powered by wall switches.

The advantage of this approach is clear logic:

The switch controls the mirror's on/off state without the need for additional control modules or complex settings. For people who are accustomed to traditional lighting control methods, the learning cost is almost zero.

5. Power and safety are the key concerns for many people

The typical power of LED bathroom mirrors is usually less than 60W, and even large models with backlight and front-light combinations rarely exceed this limit. This means that their requirements for line load are relatively mild.

At the same time, mainstream products have structurally isolated the power module from the light-emitting area. They are designed with moisture-resistant features to withstand high-humidity environments. This is also why hard-wired LED mirrors can be used as fixed lighting equipment for a long time, rather than temporary electrical products.

6. Why do some people think 'hard wiring is difficult'?

In actual feedback, negative evaluations of installation difficulty often do not stem from the mirror itself, but from the following situations:

One reason is that the original route layout is unclear and requires additional judgment or route modification.

Secondly, the wall conditions are complex, and the number of fixed points is limited.

The third is a lack of confidence in electrical operations, which amplifies psychological pressure.

In fact, from an operational perspective, hard-wired LED mirrors are no more complex than wall lamps or exhaust devices, but they are larger and require greater detail.

7. From an industry perspective, hard wiring is becoming the 'default solution'

As bathroom mirror functions continue to integrate, hard wiring is shifting from a "high-end option" to a more common configuration. It not only enhances visual completion but also unifies lighting control.

In new construction or renovation projects, reserving power points for mirrors in advance has become an increasingly common design practice, further reducing the difficulty of later installation.

8. So, how should we view the installation of hard-wired LED mirrors?

When evaluating whether professional construction is needed, the answer depends on an individual's familiarity with electrical operations. However, in terms of the process and technology, installing a hardwired LED bathroom mirror with a switch is not an unattainable project.

The real key lies in whether the preliminary judgment is sufficient and whether the steps are standardized. Once these conditions are met, the cleanliness, stability, and long-term user experience provided by hard-wired mirrors often make the installation process well worth it.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.