In the bathroom lighting upgrade plan,lighted vanity mirror have become an important feature, balancing functionality and design aesthetics. Compared with ordinary mirrors, illuminated mirrors not only serve as lighting fixtures but also involve multiple safety factors, such as power connections, waterproofing, and load-bearing fixation. Industry after-sales statistics show that most faults and safety hazards do not stem from the product itself, but from improper handling of details during installation. Understanding a standardized, replicable installation process is key to ensuring long-term, safe operation.

1. Pre installation assessment: Matching wall conditions and dimensions is the first step

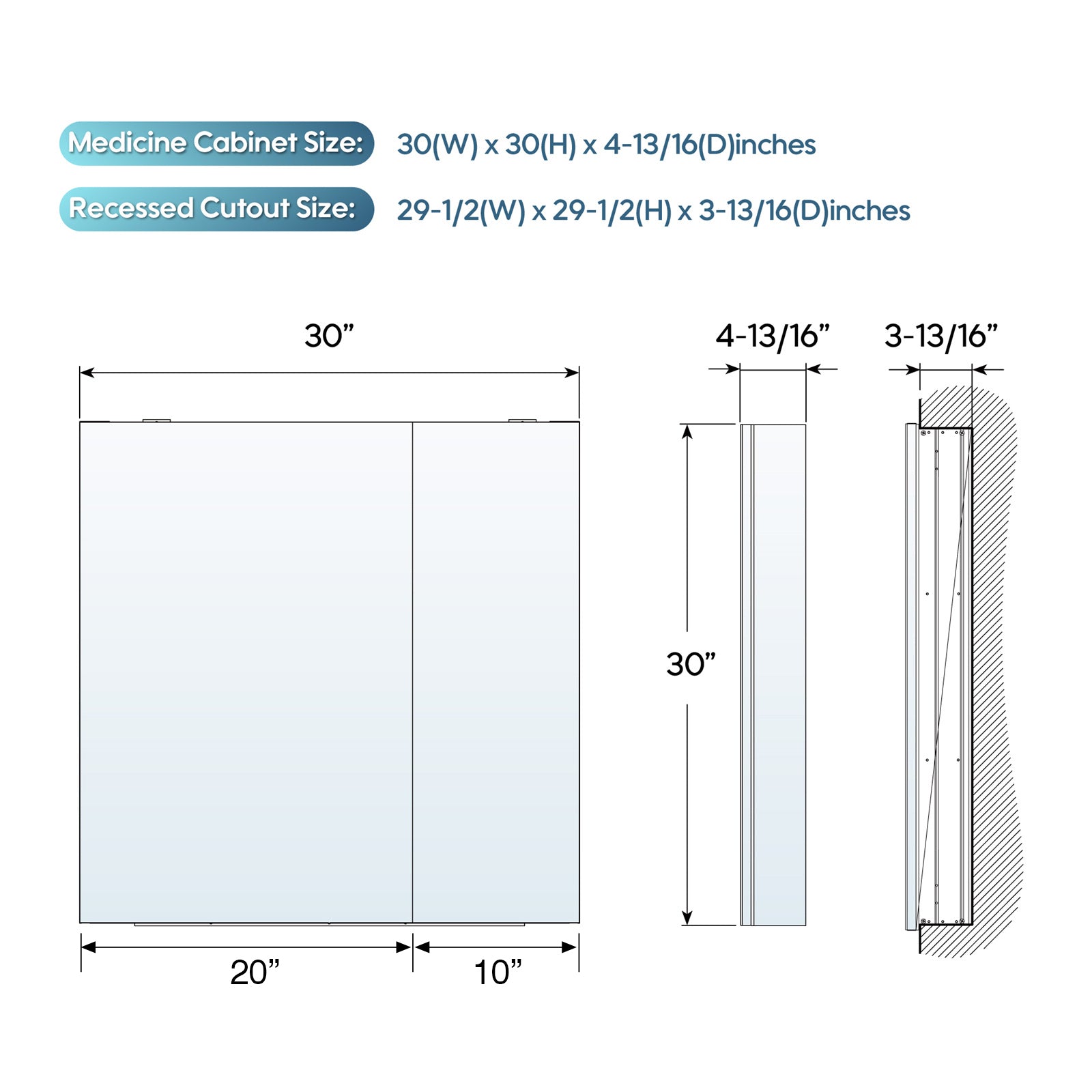

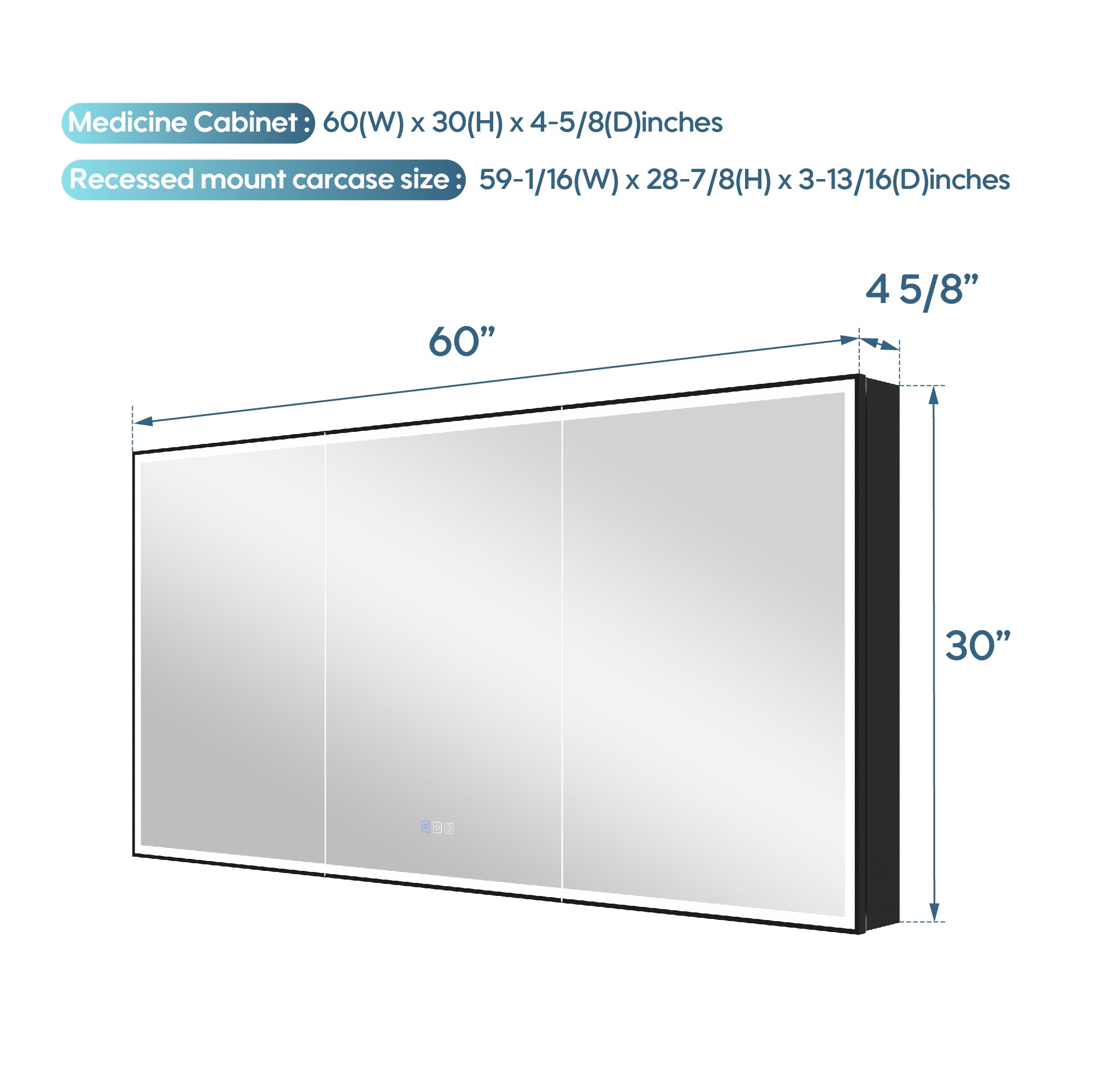

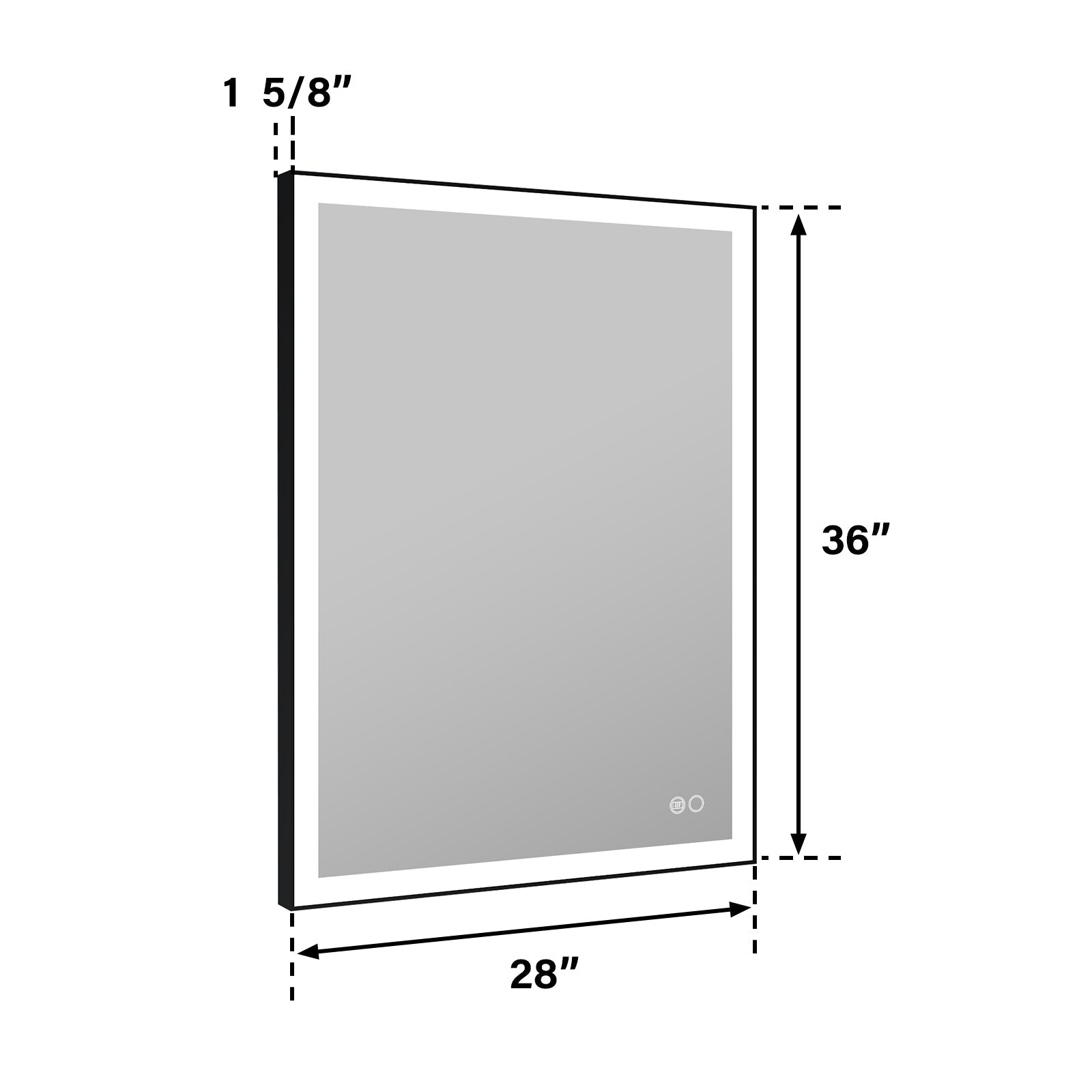

Before installation, confirm whether the wall structure has sufficient load-bearing capacity. The width of standard illuminated vanity mirrors ranges from 24 to 48 inches, and their weight is mostly between 18 and 45 pounds. Industry installation standards suggest that when the mirror width exceeds 36 inches or the weight exceeds 30 pounds, it should be fixed on at least two structural keels or dispersed with metal load-bearing anchor bolts.

At the same time, the installation height needs to be determined. Ergonomically, it is recommended to set the center height of the mirror between 60 and 65 inches from the ground, and the lower edge between 4 and 8 inches from the tabletop. This range can ensure natural visibility and reduce long-term water-stain erosion of the mirror's bottom.

2. Power mode selection: Safety is more important than aesthetics

The illuminated vanity mirror mainly uses two methods: hardwiring or a plug-in power supply. The hardwired solution has a neat appearance and is commonly used in overall decoration projects, but it requires a stable grounding system and is controlled by an independent switch. An industry analysis of electrical accidents shows that missing grounding or an incorrect neutral wire is the leading cause of early failure.

Plug-in power supply is more suitable for renovation projects. It is recommended that the socket be at least 12 inches away from the edge of the washbasin and at least 15 inches above the ground, and that a moisture-proof cover be used to reduce the risk of moisture entering the circuit.

3. Waterproof and moisture-proof treatment: key details determining service life

The long-term humidity in the bathroom is usually maintained at 60%-90%. Industry failure analysis shows that about 40% of early-damage cases involving illuminated mirrors are due to water ingress or condensation.

Standard practices include:

Reserve a ventilation gap of 1/8 inch to 1/4 inch between the mirror back panel and the wall surface

Apply waterproof sealant on the edge of the junction box

Install a waterproof sheath at the entrance of the wire

When the bottom edge of the mirror is less than 6 inches from the countertop, the bottom seal should be strengthened to prevent long-term erosion of internal components from hand washing and splashing water.

4. Fixed structure: Stability takes priority over hidden effects

Most illuminated vanity mirrors use backboard hanging strips or metal pendant structures. Industry installation standard recommendations:

Fixed point spacing not exceeding 24 inches

Single point bearing capacity not less than 50 lb

Prioritize fixing at the position of the structural keel

For large mirrors with a width exceeding 40 inches, a continuous hanging rail system is more effective at distributing weight and preventing loosening in the central area from long-term force concentration. Hollow walls must use metal expansion anchors instead of relying solely on plastic expansion plugs.

5. Control system and switch layout

Standard control methods include a touch panel and a wall-independent switch. Suggestions for industry safety standards:

The wall switch should be at least 12 inches away from the edge of the water source

The touch area should be no less than 6 inches away from the bottom edge of the mirror

All lines must be connected to a complete grounding system

In models with defogging and multi-level dimming functions, it is advisable to avoid sharing circuits with high-power devices to reduce the impact of voltage fluctuations on the driver's lifespan.

6. Power on test and final inspection

After installation, the complete testing process should be carried out:

Continuously power on for 15-30 minutes and observe for flickering or abnormal temperature rise

Test whether the brightness, color temperature, and defogging switching are stable

Check for water seepage or dew accumulation at the edges

Gently push the mirror body to confirm that there is no looseness or shaking

Industry maintenance experience shows that over 70% of later failures can be detected and corrected in advance during the first power-on stage.

7. From an industry perspective: the long-term value brought by standardized installation

Long-term usage statistics show that the stable operational cycle of a properly installed illuminated vanity mirror can generally reach 10-15 years. Malfunctions caused by improper wiring, waterproofing, or fixation often occur in the first 12 months and require complete disassembly and repair of the mirror, which is much more expensive than the initial standardized construction.

This means that safe installation is not only about electrical safety but also directly determines the product's actual lifespan and maintenance costs.

8. Conclusion

Returning to the question itself: How do I install an illuminated vanity mirror safely?

The core is not complex, but it must be systematically executed:

Evaluate the wall and load-bearing conditions

Choose the correct power supply method

Carry out waterproofing and ventilation treatment

Strictly control fixed and height standards

When all these steps are in place, an illuminated vanity mirror can remain stable and safe, providing consistent illumination over many years of use. A genuinely professional installation is never just about "installing it", but about laying a solid foundation for the next ten years of user experience.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.