Against the backdrop of contemporary bathroom design constantly evolving towards openness and transparency, glass shower door for walk in shower have become a core feature of walk-in shower rooms. Compared to traditional shower curtains or plastic partitions, glass shower doors offer significant advantages in safety, durability, and spatial performance. One of the most easily overlooked but directly affecting key parameters of the user experience is the choice of glass thickness.

1. Why is glass thickness a key concern in the industry

From an engineering and design perspective, walk-in showers typically do not rely on the bathtub's edges for support, and glass doors themselves require higher structural stability. Industry data shows that, compared to traditional framed shower doors, frameless or semi-frameless walk-in showers depend more on the strength of the glass itself.

The thickness of glass not only affects impact resistance but also the weight of the door body, the lifespan of hardware components, and the sense of security during long-term use. Improper thickness selection often leads to issues such as shaking, sinking, or poor opening in the later stages.

2. Industry range of mainstream glass thickness

At present, tempered glass used for walk-in showers in the industry is commonly available in thicknesses of 3/8 inch and 1/2 inch, with a few projects using 5/16 inch as a compromise between cost and weight.

From the overall trend, with the popularization of frameless design, 3/8 inch has gradually become a widely accepted "basic safety thickness, while 1/2 inch is more commonly used for high-end projects that require higher stability and visual quality.

3. 3/8 inch: The mainstream choice for balancing performance and practicality

In most walk-in shower applications, 3/8-inch-thick tempered glass is considered the ideal balance between performance and practicality. This thickness offers balanced performance in flexural strength, impact resistance, and weight control, and maintains good stability without relying on heavy, thick metal frames.

Industry test data shows that, compared to 1/4-inch glass, the impact resistance of 3/8-inch glass has significantly improved. At the same time, the pressure on the hinge and wall fixing points during opening and closing remains within a controllable range. That's also why many frameless walk-in shower projects default to 3/8 inch.

4. 1/2 inch: representative of stability and visual sophistication

When the walk-in shower is large, or the glass door height is close to 80 inches, some projects use 1/2-inch-thick glass. A larger thickness means higher rigidity, and the shaking sensation of the door body during opening and closing is significantly reduced.

In addition, 1/2 inch glass has a more "presence" visually, and the edge thickness forms more apparent line contours in a frameless design, which is also one of the reasons why many high-end bathroom projects prefer this specification.

However, from industry experience, thicker glass also means greater weight, which places greater demands on the wall structure, hardware strength, and installation accuracy.

5. 5/16 inch: Compromise in Specific Scenarios

5/16-inch-thick glass is not mainstream in walk-in showers, but it still has applications in some confined spaces or half-frame structures. This thickness offers greater weight control benefits, but it is more dependent on the support system and usually requires use with a metal frame or top support rod.

According to industry feedback, when 5/16-inch glass is used for frameless walk-in showers, extremely high installation accuracy is required; slight deformation or stability degradation may occur over the long term.

6. The relationship between glass thickness and shower door size

When choosing the ideal glass thickness, the door body size is an essential factor that cannot be ignored. The industry usually considers the width and height of glass doors comprehensively:

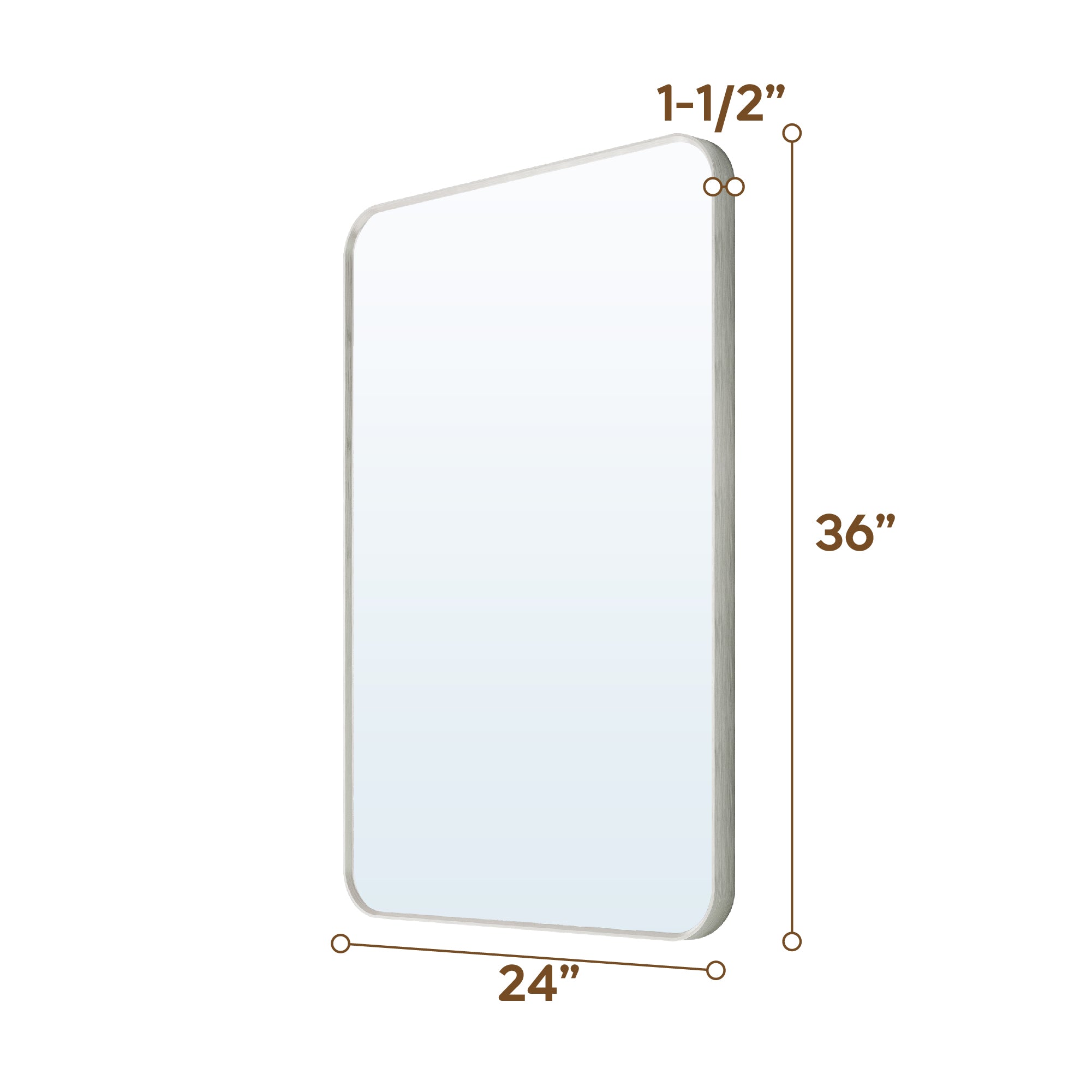

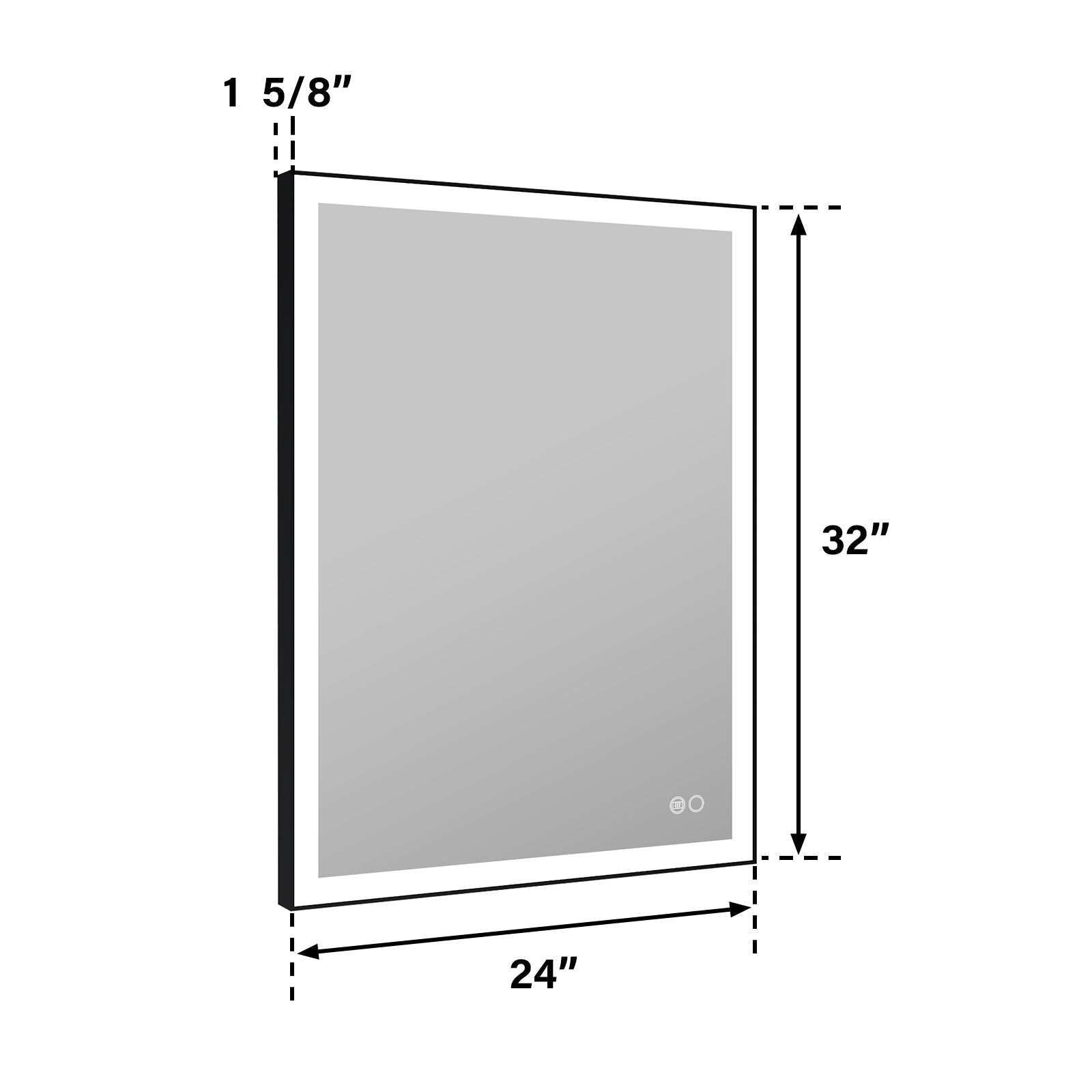

When the width of a single glass door is controlled to 24-30 inches, and the height does not exceed 72 inches, a thickness of 3/8 inch is usually sufficient to meet safety and stability requirements.

When the width approaches 36 inches or the height exceeds 78 inches, thicker glass often provides more reliable structural performance.

This principle of "size thickness linkage" has become a vital reference logic in walk-in shower design.

7. The necessity of safety standards and tempered glass

Regardless of the chosen thickness, industry consensus holds that the glass used in the walk-in shower must be tempered. Tempering treatment can significantly enhance the impact resistance of glass and form granular fragments when broken, reducing the risk of accidental injury.

Data shows that the impact resistance of tempered glass can reach several times that of ordinary glass, which is why it is considered a "non-optimal" choice in shower door applications.

8. Beyond thickness: structural design is equally crucial

It is worth noting that glass thickness is not the only factor determining safety. The quality of hardware components, the method of wall fixation, and whether top stabilizer bars are installed will all have a significant impact on overall safety.

Industry practice has shown that even with 3/8-inch glass, as long as it is paired with a reasonable support structure, its stability and durability can fully meet high-frequency usage requirements. On the contrary, relying solely on thicker glass and neglecting structural design is also difficult to achieve the desired effect.

9. Conclusion: Ideal thickness comes from systematic judgment

From an industry perspective, there is no absolute consensus on the ideal glass thickness for a glass shower door for walking in a shower. It needs to be comprehensively evaluated based on the shower room's size, structural form, frequency of use, and design goals.

In most application scenarios, 3/8 inch provides a mature and reliable solution; In projects with larger scales or higher design requirements, 1/2 inch can bring additional stability and visual value. The truly ideal choice is not 'thicker is better', but to find the most reasonable balance between safety, performance, and design.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.