In the actual operation of shower space renovation and door replacement, a 36 inch shower door is one of the most common and error-prone specifications. On the surface, "36 inch" is a standard size. Still, in real construction environments, wall verticality, ground slope, door structure, and installation tolerances all have a decisive impact on the final fit. From industry experience, the accuracy of measurement often directly determines the user experience and the incidence of later problems more than the material and price of the door itself.

1. Why is the 36-inch size the most common choice

In residential bathroom design, the standard shower opening width is typically 32-36 inches.

Among them, 36 inches is considered the balance point between traffic comfort and space efficiency:

Access is significantly restricted below 30 inches.

When it exceeds 38 inches, it can easily clog the basin or toilet drain.

Industry residential design data show that in standard single shower rooms, over 50% of the openings are concentrated in the 34-36-inch range, with 36 inches the most common nominal size for finished doors.

This also means that a 36-inch door does not mean "exactly 36 inches from wall to wall", but requires precise measurement in conjunction with the installation structure.

2. Clear differences in door structure must be identified before measurement

Before starting the measurement, it is necessary to confirm the type of door to be installed, as different structures have entirely different requirements for dimensional tolerances:

Hinged door:

A stricter net opening size is required, typically with a tolerance of no more than ± 1/4 inch.

Sliding door:

Allow for a larger adjustment range, generally covering nominal size ± 1/2 inch.

Frameless doors:

The highest requirement for wall verticality and stricter error control.

Semi-framed or framed doors:

Larger adjustment range and stronger adaptability.

Industry installation statistics show that over 60% of measurement error issues occur in projects where the door structure has not been confirmed in advance.

3. Basic measurement principle: always measure three points instead of one

When measuring a 36-inch opening, the standard procedure is to measure three key heights:

Above: about 72 inches above the ground.

Central: about 36-40 inches above the ground.

Below: about 2-4 inches from the ground.

These three positions respectively reflect:

Flatness of the upper part of the wall.

Deformation of the central wall surface.

Horizontal error between the ground and the water barrier.

Industry experience shows that in old houses or non-standard construction, it is not uncommon for the width difference between three points to exceed 3/8 inch.

The measurement principle is always to use the minimum value as the effective installation width.

Because the door can only be scaled down for adaptation, it is almost impossible to enlarge.

4. How to determine if the "36-inch door" is really suitable for your opening

Most shower doors with a nominal width of 36 inches are not fixed-width but have adjustable ranges.

The general coverage of standard products is:

Minimum installable width: 34 1/2 inches.

Maximum installable width: 36 1/2 inches.

Industry data shows that in real projects, the ideal opening size is usually concentrated between 35 and 36 inches.

When measured width:

Less than 34 1/2 inches: customization or wall modification required.

Greater than 36 1/2 inches: standard door cannot cover.

Therefore, the criterion for judgment is not "whether it is 36 inches", but:

Whether it falls within the product's effective adjustment range.

5. Verticality measurement: the most easily overlooked key indicator

The qualified width does not mean it can be installed directly.

The wall's verticality significantly impacts the door's sealing and lifespan.

The standard practice is:

Measure the verticality of the left and right walls with a level or laser.

Compare the deviation between the 72-inch height and the bottom.

Suggestions for industry installation standards:

The deviation of a single-sided wall should not exceed 1/8 inch.

The cumulative deviation on both sides should not exceed 1/4 inch.

When the vertical error exceeds this range, even if the width is correct, it is easy to encounter:

The door is not tightly closed.

Magnetic strip misalignment.

The risk of water overflow has significantly increased.

This is also the core reason why frameless doors require extremely high construction quality.

6. Ground and water barrier measurement: key details determining whether there is water leakage

In the 36-inch opening, the lower structure has a significant impact on actual use.

During measurement, it is essential to confirm:

Does the length of the water barrier cover the clear opening.

Is the water barrier completely horizontal.

Is the ground slope inclined inward.

Industry data shows that over 40% of water leakage complaints are related to horizontal errors in the water barrier, rather than defects in the door itself.

The standard recommendation is:

The horizontal error of the water blocking strip shall not exceed 1/16 inch.

The inner slope should be kept inclined toward the drainage direction.

This detail is often more important than the door's width.

7. The true difference between door leaf width and effective passage width

Many users mistakenly believe that a 36-inch door represents a "passage width of 36 inches", but in reality, this is not the case.

In different structures:

Flat door: the effective passage width is usually 24-28 inches.

Sliding door: the width for a single-sided passage is mainly 18-22 inches.

Industry ergonomics data shows that the minimum comfortable width for adults is approximately 22-24 inches.

This means:

Even with a 36-inch opening, the door design ultimately determines whether it is comfortable to enter and exit.

This is also why, in high-end projects, it is more common to choose large-opening-angle swing doors rather than narrow sliding doors.

8. The measurement influence of glass thickness and structural allowance

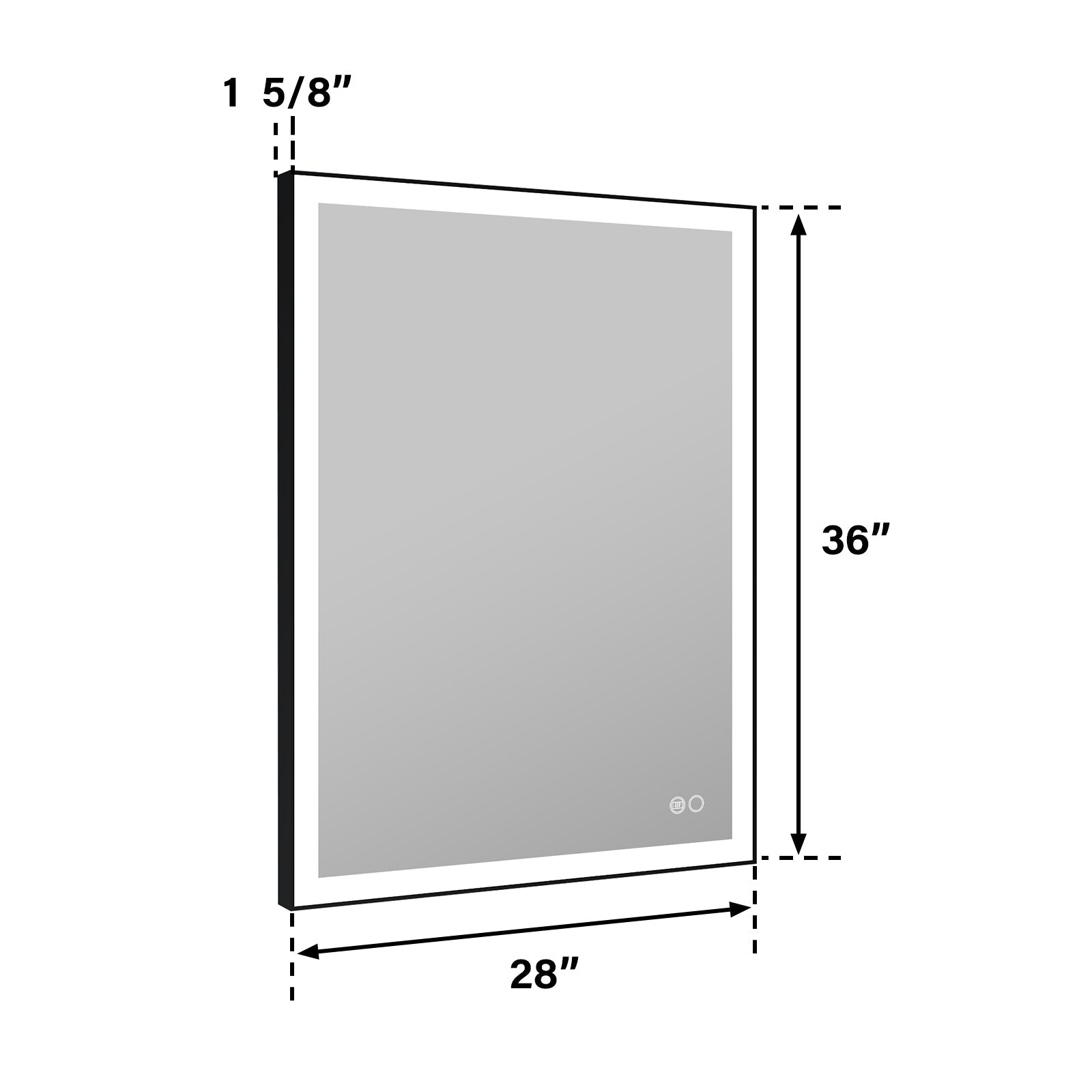

The standard glass thicknesses for 36-inch frameless doors are concentrated in:

3/8 inch.

1/2 inch.

Thick glass has higher requirements for hardware stress and installation accuracy.

Industry installation experience shows that:

In a 1/2 inch glass system, the reserved installation tolerance usually needs to be controlled within ± 1/8 inch, otherwise it may lead to:

The door hangs down.

Early wear and tear of hinges.

Closed offset.

Therefore, thick glass systems require much higher measurement accuracy than framed structures.

9. When do I need to choose custom sizes instead of finished doors

In the following scenarios, finished 36-inch doors often have higher risks:

The walls are not parallel, and the difference between the three points exceeds 1/2 inch.

Opening width less than 34 inches or greater than 37 inches.

No water barrier structure.

Complex ground slope.

Industry statistics show that in high-end residential projects, over 30% of shower doors are customized in size rather than manufactured to standard specifications.

The most significant value of customization is not its appearance, but rather:

Smaller gaps.

Better sealing.

More stable lifespan.

Conclusion: Measurement determines 90% of the success or failure of shower doors

In the shower door system, the quality of the door is undoubtedly essential, but measurement accuracy is the core factor that truly determines the long-term experience.

For a 36-inch shower door, what really needs to be confirmed is never whether it is 36 inches or not, but rather:

What is the minimum actual opening value.

Is the wall vertical.

Is the ground level.

Does the door type match.

Does the adjustment interval cover.

A set of accurate measurement data is often more effective in avoiding later water leakage, abnormal noise, sagging, and repeated rework than expensive door bodies.

In a space system that is frequently used every day and has exceptionally high maintenance costs,

Accurate measurement is itself the most important investment.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.