LED light mirror are becoming a practical addition to bathrooms and dressing areas, offering more than simple illumination. Using LED strips with light guides and diffusers, they provide uniform, glare-free lighting that improves makeup and skincare precision (source: Lighting Research Centre). Advanced processing balances light reflection and transmission, delivering clear images with soft, ample illumination.

Intelligent sensors, often passive infrared (PIR) or photodiodes, activate lighting based on motion or ambient light changes (source: IEEE Sensors Journal). Defogging uses gentle heating pads or wires to prevent condensation, ensuring mirrors remain clear during use (source: Applied Thermal Engineering). Together, these features make LED smart mirrors versatile and convenient for daily routines.

Next, we will delve into how LED smart mirrors work, focusing on their optical design, sensor-activated lighting principles, defogging mechanisms, and the core components behind them.

1. Core Operating Principles: Optical Design and Light Control

The core challenge facing LED smart mirrors is how to ensure uniform and soft light transmission through the mirror surface, illuminating the user rather than the surrounding environment, while maintaining the mirror's normal imaging function. This primarily relies on their unique optical design and mirror surface treatment.

Light Source Layout and Optical Path Design

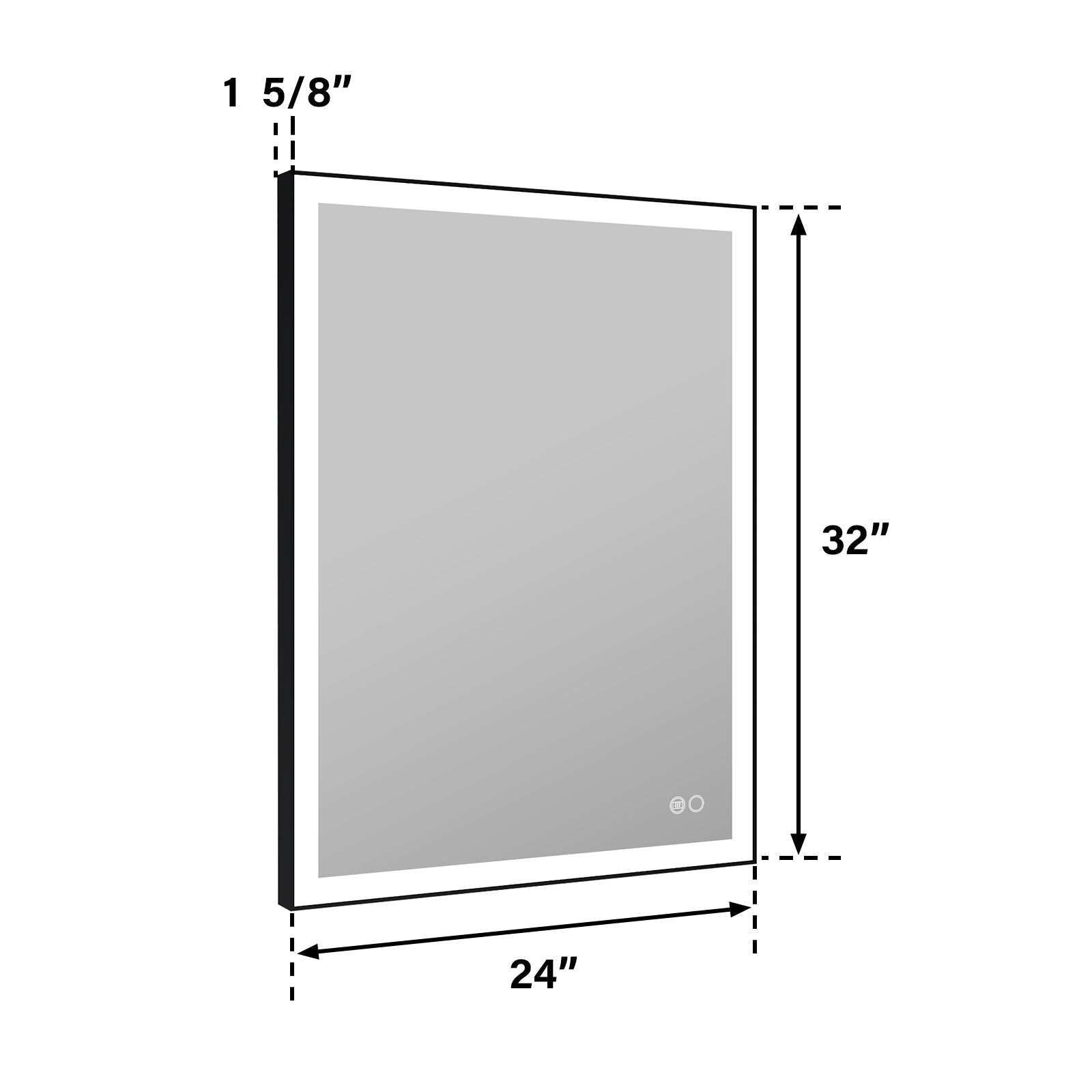

LED Strips: Most LED smart mirrors use high-density surface-mount LED strips as their light source. These strips are typically installed along the edge of the mirror.

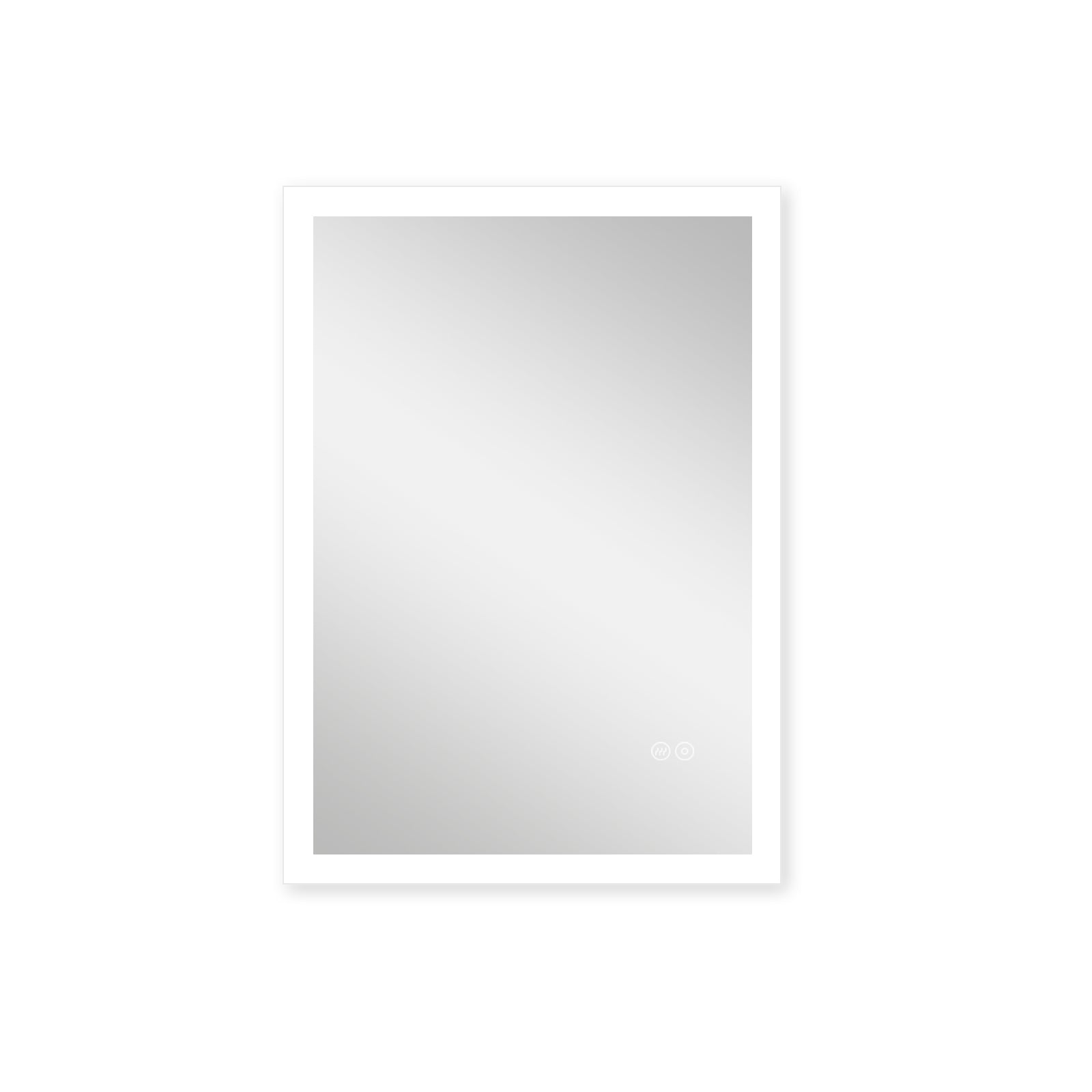

Light Guide Plates (LGPs) and Diffuser Films: To convert LED point light sources into a uniform surface light source, high-end LED mirrors utilise both LGPs and diffuser films. LGPs are typically made of highly transparent acrylic with a sophisticated microstructure that guides and diffuses light. Diffuser films further eliminate hotspots, resulting in a softer, more even light output and less glare from looking directly at the light source.

Forward Light Enhancement Technology: Some designs optimise the optical path to direct the highest-intensity forward light from the LED strip directly to specific light-transmitting areas of the lens, while using the weaker side light for ambient lighting. This significantly improves the efficiency of the mirror's front lighting.

Balancing Transmission and Reflection: Special Mirror Treatment

Lens Transparent Area: A specialised process (such as laser etching) removes a portion of the reflective layer from the back coating, creating a transparent, light-transmitting area. These areas are typically frosted and coated with a light-diffusing film, allowing light to penetrate the glass and evenly disperse toward the mirror's front.

Transflective Coating: Another option is to apply a transflective coating to the entire back of the glass. This film acts like a Venetian blind, allowing some light to penetrate the glass from behind to illuminate the user while reflecting some light back to create a clear mirror image, thus balancing illumination and imaging.

2. How Does the Sensor Lighting Function Work?

The intelligent sensing function enables the LED mirror to automatically illuminate when a user approaches and turn off after a delay, greatly improving convenience and energy efficiency. Its core technology is the sensor and corresponding control circuitry.

Sensor Technology

Passive Infrared Sensor (PIR Sensor): This is the most commonly used sensing technology. It uses the pyroelectric effect to detect infrared radiation of a specific wavelength (7-14μm) emitted by human movement.

A Fresnel lens in front of the sensor focuses the infrared signal and divides the detection area. Upon detecting human movement, the sensor generates a weak electrical signal.

Ambient Light Sensor: This sensor typically works in conjunction with a PIR sensor. It is a photoresistor (such as a CDS) that senses ambient light intensity.10 During daytime or when ambient light is bright enough, it blocks the PIR sensor's trigger signal, preventing the mirror from accidentally lighting up when not needed, thus achieving a "day and night power saving" function.10

Control Circuit and Processing Unit

The weak electrical signal generated by the sensor needs to be processed and evaluated:

Dedicated processing chip: For example, a sensor signal processing integrated circuit like the BISS0001.10. This chip performs two-stage high-gain amplification on the PIR signal, uses an internal bidirectional amplitude detector to determine the signal's validity, and ultimately outputs a control signal.

Delay and Light Control Adjustment: The processing chip typically supports setting the light-on delay (for example, Tx = 49152 × RP2 × C9)10 and the ambient light threshold required for triggering (adjustable via a potentiometer) using external resistors and capacitors (RC circuit). .10

Actuator

The control signal (high level) output by the processing chip drives a switching element (such as a transistor 9013), which in turn controls the on/off switching of the lighting circuit, for LED light panels that directly operate from AC mains power, solid-state relays (SSRs) are often used as contactless electronic switches to achieve safe and efficient control.

3. How Does the Defogger Function Work?

Bathroom mirrors fog up because water vapour condenses into small droplets on the cool mirror surface. The defogger function of LED smart mirrors solves this problem by actively heating the mirror surface.

Heating Element

A metal heating film or heating demisting pad is typically applied to the back of the mirror.

This heating film is typically evenly applied to a specific area on the back of the mirror. When powered, it generates heat and warms the mirror surface.

Working Principle

Raising the Mirror Temperature: When powered, the heating film activates, raising the mirror surface temperature to a level slightly above the ambient bathroom temperature (usually above room temperature).

Preventing Condensation: According to physical principles, when the mirror surface temperature is above the dew point of the surrounding air, water vapour cannot condense on its surface, maintaining a clear mirror surface.

Intelligent Control: The defogger function is often integrated with the lighting system. Some models automatically activate the defogger pad when the LED light is on.

4. Light Adjustment and Other Intelligent Features

Many LED smart mirrors also allow users to customise the colour temperature and brightness of the light to suit different scene requirements.

Colour Temperature Adjustment: Light strips typically integrate LED chips with different colour temperatures (e.g., 2700K warm yellow to 6500K cool white). By varying the current or lighting combination of different chips through a controller, the colour temperature can be adjusted continuously or in steps over a wide range.

Brightness Adjustment: PWM (Pulse Width Modulation) or analogue dimming techniques are used to continuously adjust the light brightness by varying the LED drive current or duty cycle.

Interaction Methods: In addition to sensor-based control, many mirrors also offer touch switches or gesture recognition (wave to switch modes) for more sophisticated operation.

Conclusion

The operating principle of the LED smart mirror is a brilliant fusion of optics, electronics, materials science, and intelligent control technology. From the uniform illumination provided by the light guide plate and diffuser film, to the automatic sensing enabled by the pyroelectric sensor; from the mist dissipated by the heated defogging pad, to the stable light and shadow guaranteed by the mirror constant current circuit—every detail is designed to provide users with a clearer, more convenient, and more comfortable user experience.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.